Introduction to Compact Drilling Machines

Compact drilling machines are versatile tools used in various industries for precise drilling operations. These machines offer a combination of power, portability, and magnetic clamping capabilities, making them ideal for both on-site and workshop applications. In this article, we will explore the features, benefits, and applications of compact drilling machines, with a focus on the PRO-36 model by Promotech India. compact drilling machine, portable drilling machine, heavy duty cordless drill machine

Overview of Compact Drilling Machines

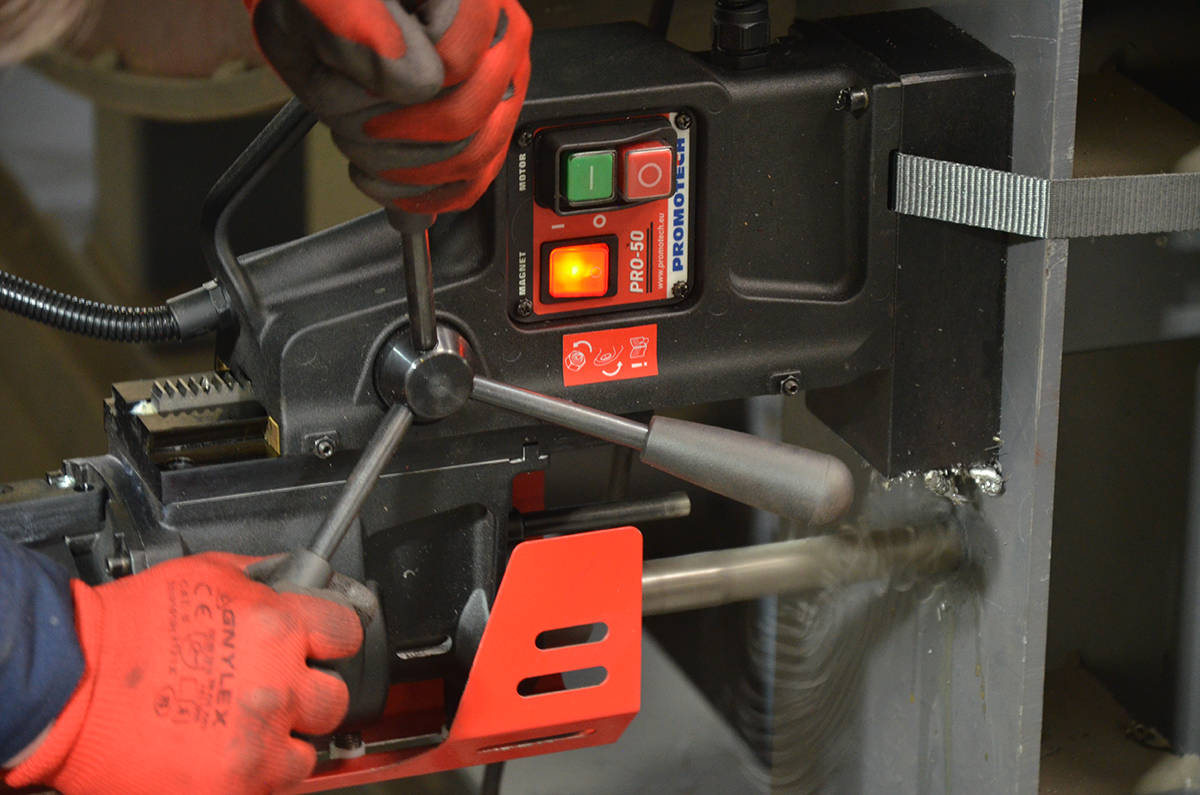

Compact drilling machines or portable drilling machines by Promotech India, are designed to provide efficient and accurate drilling operations in tight spaces. These machines utilize annular cutters or twist drill bits with Weldon shank to create holes in a range of materials. The PRO-36 model, manufactured by Promotech India, is a popular choice among customers due to its compact design, lightweight construction, and high-performance features. compact drilling machine, portable drilling machine, heavy duty cordless drill machine

Features of Compact Drilling Machines

The PRO-36 compact drilling machine is equipped with several features that enhance its functionality and performance. These features include:

- Dual Bars Guide System: The PRO-36 incorporates a dual bars guide system that ensures extraordinary stiffness and adjustment-free operation. This design element contributes to the

machine’s stability and accuracy during drilling operations.

- 2. Versatile Application: Compact drilling machines can be used for a wide range of drilling operations, including out of position drilling, pipe drilling, and close-quarter drilling. The PRO-36’s versatility makes it a valuable tool for professionals working on different projects.

3. Magnetic Field Shape Control (MFSC): The PRO-36 is equipped with MFSC technology, which provides maximum holding power on thin materials. This feature ensures stability and precision during drilling operations, even on delicate workpieces.

4. Magnetic Power Adhesion Control (MPAC): The MPAC feature of the PRO-36 detects the adhesive force of the electromagnetic base, protecting both the machine and the operator from work on too thin workpieces. This safety measure prevents damage to the equipment and ensures operator well-being. compact drilling machine, portable drilling machine, heavy duty cordless drill machine

Applications of Compact Drilling Machines

Compact drilling machines find applications in various industries and sectors. The PRO-36, with its versatile capabilities, can be used in the following applications:

1. Metal Fabrication: Compact drilling machines are commonly used in metal fabrication processes, such as drilling holes for fasteners, creating openings for electrical conduits, or adding holes for cable routing. compact drilling machine, portable drilling machine, heavy duty cordless drill machine

2. Construction and Engineering: In construction and engineering projects, compact drilling machines are essential for tasks like installing handrails, creating openings for pipes and conduits, or drilling holes for structural connections.

3. Automotive and Aerospace: The PRO-36 can be utilized in automotive and aerospace industries for drilling holes in vehicle frames, engine components, or aircraft structures. Its compact size and portability make it suitable for both factory and on-site applications.

4. Maintenance and Repair: Compact drilling machines are valuable tools for maintenance and repair work, allowing professionals to drill holes in equipment, machinery, or infrastructure for repairs or modifications. compact drilling machine, portable drilling machine, heavy duty cordless drill machine

Benefits of Compact Drilling Machines

The use of compact drilling machines, such as the PRO-36, offers several benefits to professionals in various industries. These benefits include:

1. Maintenance-Friendly Design: The PRO-36 features a maintenance-friendly design, making it easy to use and service. This aspect reduces downtime and ensures optimal performance throughout the machine’s lifespan.

2. Versatile Application: Compact drilling machines can be used for a wide range of drilling operations, including out of position drilling, pipe drilling, and close-quarter drilling. The PRO-36’s versatility makes it a valuable tool for professionals working on different projects.

3. Magnetic Field Shape Control (MFSC): The PRO-36 is equipped with MFSC technology, which provides maximum holding power on thin materials. This feature ensures stability and precision during drilling operations, even on delicate workpieces.

4. Magnetic Power Adhesion Control (MPAC): The MPAC feature of the PRO-36 detects the adhesive force of the electromagnetic base, protecting both the machine and the operator from work on too thin workpieces. This safety measure prevents damage to the equipment and ensures operator well-being. compact drilling machine, portable drilling machine, heavy duty cordless drill machine

Technical Specifications of the PRO-36 Compact Drilling Machine

To understand the capabilities of the PRO-36 compact drilling machine in more detail, let’s explore its technical specifications.

How to Use a Compact Drilling Machine

Using a compact drilling machine like the PRO-36 requires following a few simple steps:

- Preparation: Ensure that the workpiece is securely positioned and the machine is properly set up. Check that the magnetic base has a strong adhesion to the work surface.

- Select the Cutting Tool: Choose the appropriate annular cutter or twist drill bit with Weldon shank for the desired hole size and material.

- Adjust the Depth and Speed: Set the desired drilling depth and adjust the motor speed according to the material being drilled. Refer to the manufacturer’s guidelines for recommended speed settings.

- Start Drilling: Turn on the machine and begin drilling, applying moderate pressure to maintain control and prevent overheating. Use coolant or lubricant as recommended for better cutting performance and tool longevity.

- Monitor Progress: Monitor the drilling process, ensuring that the cutting tool is functioning properly and the desired hole dimensions are being achieved.

- Complete the Drilling Operation: Once the drilling is complete, carefully retract the cutting tool and switch off the machine. Clean the work area and remove any debris or coolant. compact drilling machine, portable drilling machine, heavy duty cordless drill machine

Maintenance and Safety Considerations

To ensure optimal performance and safe operation, it is essential to follow proper maintenance and safety guidelines for compact drilling machines. Here are some key considerations:

Maintenance

- Regularly inspect the machine for any signs of wear or damage. Replace worn-out parts promptly.

- Clean the machine after each use to remove any debris or coolant.

- Lubricate moving parts as recommended by the manufacturer.

- Store the machine in a clean and dry environment, away from moisture and extreme temperatures.

Safety

- ays wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Familiarize yourself with the machine’s safety features and operating instructions.

- Ensure that the workpiece is securely clamped and positioned before starting drilling operations.

- Keep hands and other body parts clear of the rotating cutting tool.

- In case of any issues or abnormalities, stop using the machine and seek professional assistance.

Promotech Machines are as follows:

- PRO-16 | 2-speed Drilling Machine

- PRO-36 Battery | Cordless Drilling Machine

- PRO-40 | Universal Drilling Machine

- PRO-50 | 2-speed Drilling Machine

- PRO-50 TCT | 2-speed Drilling Machine

- PRO-55 | Annular Cutter Drilling Machine

- PRO-55 TCT | Annular Cutter Drilling Machine

- PRO-36 AD | Ultra Low Profile Mag Drill

- PRO-36 Auto | Auto Feed Mag Drill With Led Monitoring System

- PRO-36 | Compact Mag Drill

- PRO-36 | Drills for Special Applications

- PRO-62 | Annular Cutter Drilling Machine

- PRO-72 | Two-Speed Drilling Machine

- PRO-111 | Heavy Duty Mag Drill

- PRO-52T | Universal Tapping and Drilling Machine

- PRO-72T | Versatile Drilling & Tapping Machine

- PRO-122T | Industrial Tapping and Drilling Machine

- PRO-152T | Heavy Duty Tapping and Drilling Machine

- PRO-36RH | Petrol Motor Rail Drill

- PRO-36R | Electric Motor Rail Drill

- PRO-35 ADA ATEX | Pneumatic Mag Drill

- PRO 45/2 ATEX | Pneumatic Drilling Machine

- PRO-200A ATEX | Pneumatic Mag Drill

- PRO-60 HP | Portable Hydraulic Punchers

- PRO-110 HP | Portable Hydraulic Punchers

Conclusion:

Compact drilling machines, such as the PRO-36 by Promotech India, offer a powerful and portable solution for drilling operations in various industries. Their compact design, lightweight construction, and advanced features make them ideal for on-site work and tight spaces.

By understanding the technical specifications, applications, and proper usage guidelines, professionals can maximize the benefits of these versatile tools. Remember to prioritize safety and follow maintenance protocols to ensure long-term performance and durability. Invest in a compact drilling machine to enhance your productivity and efficiency in drilling operations. compact drilling machine, portable drilling machine, heavy duty cordless drill machine

If you are considering robotic welding and cutting solutions for your business, mail us at info.pfm@promotech.eu or visit Promotech India for more information.

machine’s stability and accuracy during drilling operations.

machine’s stability and accuracy during drilling operations.