Is it safe to say that you are worn out on with nothing to do and exertion on loose cuts?

Look no further because we have the extreme answer for you – the TCT Cutter. In this exhaustive aid, we will take you through all that you want to be aware of to dominate accuracy cuts utilizing this game-evolving instrument.

What is a TCT Cutter?

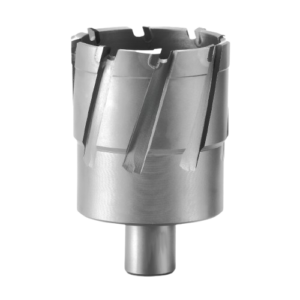

A TCT (Tungsten Carbide Tipped) cutter is a cutting device with tungsten carbide teeth that are brazed onto a steel body. This blend of materials makes TCT cutters very strong and durable. The tungsten carbide teeth are staggeringly sharp and can endure high temperatures and scraped areas, making them ideal for slicing through extreme materials.

TCT cutters come in different shapes and sizes, each intended for explicit cutting applications. They are ordinarily utilized in carpentry, metalworking, and plastic creation businesses because of their capacity to give perfect, exact cuts.

TCT cutters come in various shapes and sizes, each designed for

specific cutting applications. They are commonly used in

woodworking, metalworking, and plastic fabrication industries

due to their ability to provide clean, precise cuts.

Benefits of using TCT cutters

Utilizing a TCT cutter offers a few benefits over conventional cutting instruments. Their tungsten carbide teeth, right off the bat, are altogether more honed and harder than customary steel edges,

taking into account cleaner and more exact cuts. This lessens the need for extra completing work and saves important time.

Furthermore, TCT cutters have a more extended life expectancy contrasted with other cutting apparatuses. The blend of tungsten carbide teeth furthermore, a tough steel body guarantees that these cutters would be able to endure weighty use without losing their front line. This strength converts into cost reserve funds as the need might arise to be supplanted less as often as possible.

One more advantage of TCT cutters is their adaptability. They can be utilized to slice through an extensive variety of materials, including wood, plastic, and, surprisingly, metal. This makes them a significant device for experts furthermore, Do-It-Yourself aficionados the same, as they kill the requirement for various specific cutting devices. ter

Different types of TCT cutters

TCT cutters are accessible in different sorts to suit different cutting necessities. Here are probably the most normal sorts:

- Circular Saw Blades: Round saw sharp edges are utilized in handheld roundabout saws and table saws. They are great for making long, straight cuts in wood and different materials.

- Router bits: Switch pieces are utilized with switches to make enhancing edges, joints, and depressions in wood. They arrive in a large number of shapes and sizes to accomplish various impacts.

- Hole Saws: Opening saws are utilized for cutting enormous openings in materials like wood, plastic, and metal. They are regularly utilized in plumbing, electrical, and development work.

- Planer knives: Planer blades are utilized in carpentry machines called planers to smooth also, level the outer layer of harsh wood.

While picking a TCT cutter, it’s critical to think about the particular cutting job needing to be done and select the proper sort and size of cutter for the gig.

Choosing the right TCT cutter for your project

Choosing the right TCT cutter for your task is essential to accomplishing exact and clean cuts. Here are a few elements to consider while picking a TCT cutter::

- Material: Consider the sort of material you will cut. Unique materials require different TCT cutters. For instance, a TCT cutter intended for wood may not be appropriate for

cutting metal. - Size: The size of the TCT cutter ought to match the thickness of the material you are working with. Utilizing a cutter that is too small might bring about inadequate cuts, while utilizing a cutter that is too huge may cause harm to the material or the actual cutter.

- Tooth Setup: TCT cutters accompany different tooth setups, like fine, medium, and coarse. The tooth design decides the completion of the cut. Better tooth setups are appropriate for spotless and smooth cuts, while coarser tooth arrangements are better for unpleasant cuts.

- Speed and Feed Rate: Consider the speed and feed rate at which the TCT cutter will be utilized. Higher velocities and feed rates are appropriate for milder materials, while slower paces and feed rates are better for more enthusiastic materials.

By taking into account these variables, you can pick the right TCT cutter for your undertaking and guarantee exact furthermore, productive cutting.tct cutters, tct annular cutter, tct hole cutter, tct annular cutter price, tct broach cutter, tct core cutter

How to use a TCT cutter effectively

Utilizing a TCT cutter requires a legitimate method and tender loving care. Here are a few hints to assist you with taking advantage of your TCT cutter:

- Prepare the workpiece: Guarantee that the workpiece is appropriately gotten and upheld previously making any cuts. This will keep it from moving or vibrating during the cutting system, guaranteeing spotless and exact cuts.

- Mark the cutline: Utilize a pencil or checking device to stamp the cutline on the workpiece. This will act as an aide and assist you with accomplishing exact cuts.

- Start with a shallow cut: While involving a TCT cutter interestingly or slicing through a thick material, it’s prudent to begin with a shallow cut. This will assist you with checking the presentation of the cutter and forestall any possible harm.

- Maintain a steady pace: Move the TCT cutter along the noticeable cut line at a consistent and reliable speed. Abstain from surging or faltering, as this can bring about lopsided slices or harm to the cutter.

- Use the appropriate cutting technique: Different cutting strategies might be required contingent upon the sort of TCT cutter and the material being cut. For instance, while utilizing a round saw edge, a smooth and consistent cutting movement is suggested, while utilizing an opening saw may require intermittent stopping to clear trash.

By observing these rules, you can guarantee that you are utilizing your TCT cutter successfully and accomplishing exact cuts easily. tct cutters, tct annular cutter, tct hole cutter, tct annular cutter price, tct broach cutter, tct core cutter

Safety precautions when using TCT cutters

While TCT cutters are profoundly proficient and powerful cutting apparatuses, focusing on safety is significant while utilizing them. Here are some wellbeing safeguards to remember:

- Wear protective gears: Consistently wear well-being goggles, gloves, and a residue cover while utilizing a TCT cutter. This will safeguard your eyes, hands, and respiratory framework from potential perils, for example, flying flotsam and jetsam and residue.

- Ensure proper ventilation: While working with TCT cutters, ensure you are in a well-ventilated region or utilize a fitting residue extraction framework. This will assist with limiting the inward breath of destructive residue particles.

- Read the manufacturer’s instructions: Find out about the maker’s directions and suggestions for utilizing the particular TCT cutter you have. That’s what this will guarantee you are utilizing the apparatus accurately and securely.

- Secure the workpiece: Consistently secure the workpiece appropriately before making any cuts. This will keep it from moving or moving during the cutting system, lessening the gamble of mishaps or wounds.

- Handle with care: TCT cutters have sharp teeth, so handle them with care to stay away from coincidental cuts or wounds. Continuously get your hands and fingers far from the cutting region.

By following these security safety measures, you can limit the gamble of mishaps and wounds while utilizing TCT cutters.

Maintenance and care of TCT cutters

Legitimate support and care are fundamental to guarantee the life span and execution of your TCT cutter. Here are some maintenance tips to keep in mind:

- Clean after each utilization: In the wake of utilizing a TCT cutter, clean it completely to eliminate any flotsam and jetsam or buildup. This will forestall development that can influence the cutter’s exhibition.

- Review for damage: Consistently examine the TCT cutter for any indications of harm, for example, chipped or missing teeth. If you notice any harm, supplant the cutter quickly to keep up with ideal cutting execution.

- Sharpen when necessary: Over the long haul, the tungsten carbide teeth of a TCT cutter might turn dull. At the point when this occurs, hone the teeth utilizing a jewel document or a particular honing device. This will re-establish the front line and guarantee perfect and exact cuts.

- Store properly: When not being used, store your TCT cutter in a spotless and dry spot. Keep it in its unique bundling or utilize a devoted stockpiling case to shield it from harm and residue.

By following these upkeep tips, you can delay the life expectancy of your TCT cutter and guarantee reliable cutting execution.

Common mistakes to avoid when using TCT cutters

While TCT cutters are intended to convey exact and clean cuts, certain mix-ups can think twice about their presentation.

- Using excessive force: TCT cutters are intended to cut proficiently with insignificant power. Utilizing over-the-top power can make the cutter tie or payoff, bringing about lopsided cuts or mishaps. Let the cutter accomplish the work and try not to apply pointless strain.

- Neglecting to secure the workpiece: Neglecting to appropriately get the workpiece can prompt vibrations or development during cutting, bringing about mistaken cuts or likely wounds. Continuously guarantee the workpiece is safely braced or held set up.

- Ignoring safety precautions: Well-being ought to constantly be a first concern while utilizing TCT cutters. Overlooking security precautionary measures, for example, not wearing defensive stuff or working in a perilous climate, can prompt mishaps or wounds. Continuously keep wellbeing rules and focus on your prosperity.

- Skipping maintenance: Ordinary upkeep is critical for the exhibition and life span of your TCT cutter. Failing to clean, assess, and hone the cutter can prompt decreased cutting proficiency and untimely wear.

By avoiding these common mistakes, you can ensure that you are using your TCT cutter effectively and getting the most out of its cutting capabilities. tct cutters, tct annular cutter, tct hole cutter, tct annular cutter price, tct broach cutter, tct core cutter

Promotech India: Your Source for Premium TCT Cutters

When it comes to acquiring high-quality TCT Cutters, look no further than Promotech India. With a reputation for excellence and reliability, Promotech India offers a wide range of TCT Cutters meticulously crafted to meet the demands of various cutting applications. Promotech India provides the tools you need to achieve precision cuts with ease. Visit their website today to explore their extensive collection and elevate your cutting experience.

Conclusion: Become a master of precision cuts with TCT cutters

The TCT Cutter is a powerful tool that can revolutionize your cutting experience. Its razor-sharp tungsten carbide teeth and durable steel construction make it the ideal choice for achieving clean and precise cuts in a variety of by understanding the different types of your project, using it effectively, and becoming a master of precision cuts. through regular maintenance and compromise its performance. With the TCT Cutter in your toolkit, you hello to professional-looking results. and take your cutting skills to the next providing the tools you need to achieve materials. TCT cutters, choosing the right cutter for following safety precautions, you can Remember to take care of your TCT cutter avoid common mistakes that can say goodbye to imprecise cuts, and get ready to elevate your craftsmanship level with the TCT Cutter. Promotech India precision cuts with ease. Visit their website today to explore their extensive experience. collection and elevate your cutting.

HAPPY CUTTING!!!

If you are considering robotic welding and cutting solutions for your business, mail us at info@pfm.promotech.eu or visit Promotech India for more information.