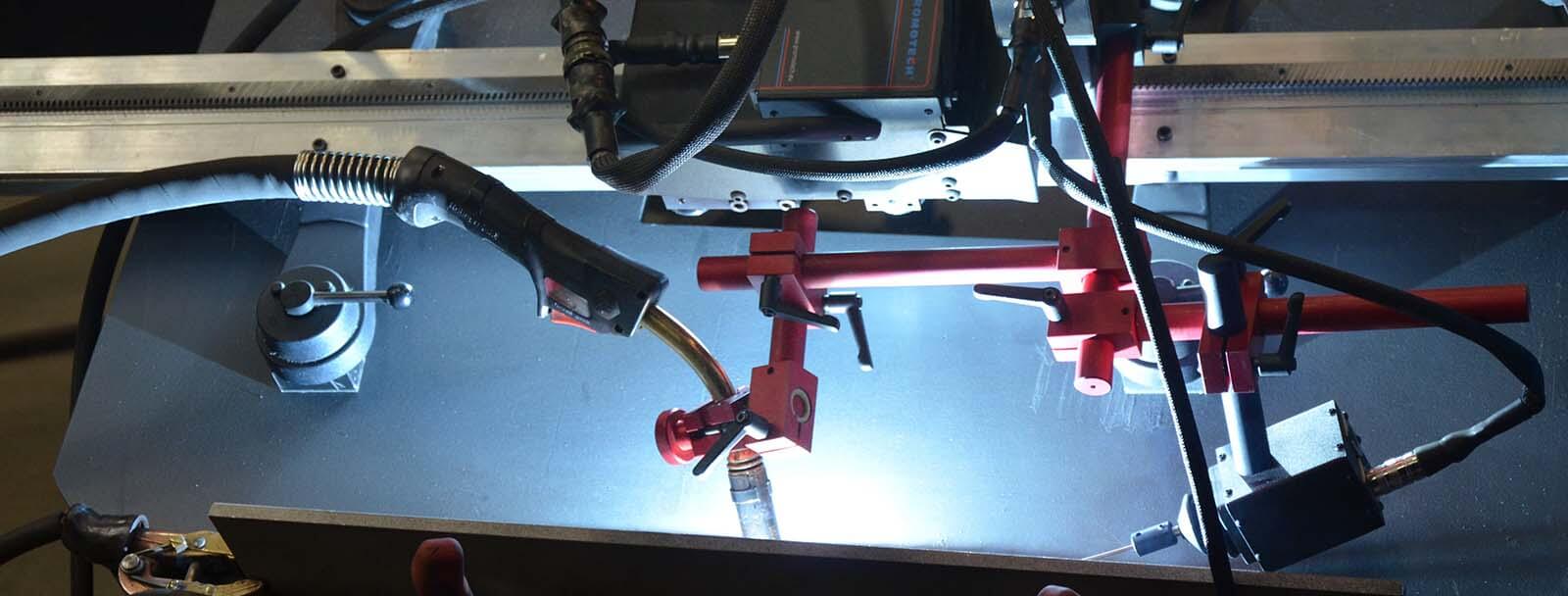

Orbital Welding System – 5G/6G MIG/MAG welding

Promotech’s carriage is dedicated to Penstock I.O/O.D welding, pipe to pipe 5G/6G welding, and pipe to flange welding.

Promotech’s carriage is suitable for a variety of circumferential and irregular surface applications down to a minimum radius of 100 mm (4 inches). Followings are the variety of tracks available with our carriage

- Ring tracks on diameters from 200 mm (8”) O.D up to 3 m (10 ft) O.D

- Custom rolled tracks on diameters from 3 m (10 ft) O.D up to 10 m (32 ft) O.D

- Semi-flexible tracks can be flexed to a minimum radius of 5 m (16 ft) without permanent deformation

Primary features and benefits:

- A fully modular mechanized travel tractor can be custom configured for a variety of welding, thermal cutting and gouging applications on a flat or curved plate, tube and pipe

- Linear torch oscillator to produce weave welds

- Active compensation of torch position vertically and horizontally by means of modular automatic seam tracking system

- Programmable path of stitch welds

- Possibility to select one limit switch preset out of three presets available.

- Ergonomic remote control pendant with simple and easy to find control knobs makes adjustments possible without the lifting of the operator welding hood

- Magnetic adhesion of the pendant provides a firm grip on ferromagnetic materials

- Suitable for all welding positions on both ferromagnetic and non-ferromagnetic materials thanks to rack and pinion drive and various tracks equipped with magnetic or vacuum units

- Promotech’s carriage produces consistently high-quality welds and cuts in a fraction of the time required by manual operations

- High speed up to 3 m/min makes plasma cutting available

Promotech’s carriage overview

- Easy to upgrade modular design

- Continuous and programmable path of stitch welds (weld length, space between welds, backweld length, crater fill time)

- Linear torch oscillator to produce weave welds

- Three modes of automatic seam tracking (vertically, horizontally and both)

- Limit switch stops the arc and travels the tractor to the initial position

- Hand-held ergonomic control pendant (3 m cable included) with magnetic adhesion provides a firm grip on ferromagnetic materials

- Multifunctional LED display with numeric representations for each motion parameter makes presetting and repeating of the optimum welding or cutting procedure simple and without guess work

- Intuitive software with a user-friendly interface

- Automatic Arc on/off initiates welding and travel simultaneously

- Rack and pinion drive

- Convenient external 230-V, 115-V, or 42-V power supply

- Closed-loop position control system based on the electric motor with encoder ensures increased accuracy of speed

- and position

- Consistent heat input reduces distortion

- Reduces wasted filler metal – eliminates over welding

- Quick-clamping torch holder mechanism for different types of MIG/MAG torches with diameters of 16-22 mm

- (0.63-0.87”); up to 35 mm (1.38”) option

- Precise torch adjustment

- Improves working environment – removes the operator from heat and fumes