Metalworking machines play a crucial role in various industries, from construction to manufacturing. They facilitate accurate countersinking, bevelling, welding, cutting, and shaping of metal parts. However, the dangers in metal workshops are as sharp as the materials they handle. From crushing injuries to harmful fumes, the risks are real and ever-present.

This article provides vital safety precautions and case studies on the proper usage of metalworking machines, such as welding carriages, bevelers, and other industrial tools, including safety measures while welding, bevelling, countersinking, and laser cutting. This guide will help you ensure the safe use of metalworking machines.

Types of Metalworking Machines

Metalworking machines come in various types, each designed for specific tasks:

- Cutting Machines: Laser cutters, plasma cutters, water jet cutters, shears.

- Forming Machines: Press brakes, roll formers, tube benders.

- Joining Machines: Welding machines, riveting machines.

- Machining Centers: CNC milling machines, CNC lathes.

Metalworking machines typically consist of:

- Base and Frame: Provides stability.

- Power Source: Drives operations.

- Control System: Manages functions.

- Tooling: Performs the work.

- Safety Guards: Protect operators.

Identifying Potential Safety Hazards

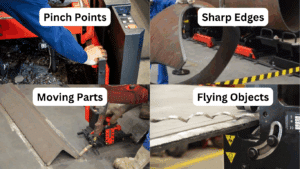

- Mechanical Risks

Mechanical dangers include:

- Pinch points

- Sharp edges

- Moving parts

- Flying objects

| Risk | Preventive Measure |

| Pinch points | Use machine guards and keep hands away from danger zones. |

| Sharp edges | Wear cut-resistant gloves and handle materials carefully. |

| Moving parts | Ensure proper machine guarding and never reach into operating machinery. |

| Flying debris | Wear safety glasses and use protective shields. |

- Electrical Hazards

Electrical hazards can cause shocks and burns:

- Exposed wiring

- Faulty equipment

- Wet conditions near electrical components

- Chemical and Material-Related Dangers

Working with metals exposes workers to:

- Metal fumes and dust (especially during welding and laser cutting)

- Cutting fluids and coolants

- Solvents and cleaning agents

- Ergonomic Concerns

Ergonomic problems can cause long-term health issues:

- Repetitive motions

- Awkward postures

- Heavy lifting

Implementing Essential Safety Measures to Ensure Safe Use of Metalworking Machines

- Understand the Machine: Study the user manual and understand its operation and associated hazards.

- Inspect the Machine Before Use: Check moving parts, safety guards, emergency stops, and clean the machine.

- Wear Appropriate Protective Gear (PPE):

- Safety glasses or face shield (essential for safety measures while laser cutting, bevelling, countersinking, and welding)

- Ear protection

- Gloves (especially important for safety measures while welding and handling sharp edges)

- Steel-toe boots

- Appropriate clothing (no loose clothing or jewelry)

- Proper Setup of Machines: Secure the workpiece, adjust machine settings, and ensure accurate alignment.

- Know the Speed and Feed Rates: Follow recommendations for the specific material and job.

- Concentrate and Maintain Vigilance: Avoid distractions and keep fingers away from moving parts.

- Maintain Cleanliness and Orderliness: Remove clutter and organize hoses and cables.

- Be Prepared for Emergencies: Know how to stop the machine quickly and access first aid.

Safe Material Handling Techniques

Safe Material Handling Techniques

Here is the information formatted into a table with the “Safe Material Handling Techniques” section:

| Safe Material Handling Techniques | Description | Benefits |

| Understand the Machine | Study the user manual and understand its operation and associated hazards. | Reduces strain and risk of injury. |

| Inspect the Machine Before Use | Check moving parts, safety guards, emergency stops, and clean the machine. | Prevents malfunction and ensures safe operation. |

| Wear Appropriate Protective Gear (PPE) | – Safety glasses or face shield (for laser cutting, welding, etc.) | Protects against cuts, impacts, and flying debris. |

| – Ear protection | Reduces noise exposure. | |

| – Gloves (for welding and sharp edges) | Protects hands from burns, cuts, and abrasions. | |

| – Steel-toe boots | Prevents foot injuries. | |

| – Appropriate clothing (no loose clothing or jewellery) | Prevents entanglement in moving machinery. | |

| Proper Setup of Machines | Secure the workpiece, adjust machine settings, and ensure accurate alignment. | Ensures precision and reduces errors. |

| Know the Speed and Feed Rates | Follow recommendations for the specific material and job. | Optimizes performance and reduces wear and tear. |

| Concentrate and Maintain Vigilance | Avoid distractions and keep fingers away from moving parts. | Prevents accidents and injuries. |

| Maintain Cleanliness and Orderliness | Remove clutter and organize hoses and cables. | Reduces tripping hazards and improves workflow. |

| Be Prepared for Emergencies | Know how to stop the machine quickly and access first aid. | Enables quick response to accidents. |

Proper Use and Storage of Tools

- Use tools for their intended purpose.

- Regularly inspect tools for damage.

- Store tools in designated areas.

- Keep cutting tools sharp and clean.

- Follow manufacturer’s maintenance specifications.

Creating a Safety-Focused Work Environment

- Developing Safety Policies: Create a written safety manual, conduct regular safety training, and have a system for updating policies.

- Encourage Employee Participation: Form safety committees, organize safety suggestion programs, and recognize safe practices.

Conclusion

Safety is paramount when using metalworking machines. Strict safety procedures, machine knowledge, concentration, and proper PPE significantly reduce injuries. By understanding the machines, identifying hazards, and implementing safeguards, accidents can be minimized. Creating comprehensive safety procedures and promoting a safety-conscious work environment are crucial.

Remember: Safety is everyone’s responsibility. Follow best practices to ensure a safe working environment. This includes specific safety measures while welding, safety measures while bevelling, safety measures while countersinking, and safety measures while laser cutting.

We at PROMOTECH work hard to make all our products and solutions safe. Our machines come with safety features that will help the operators in maintaining control and avoiding risks, be it deforming machines, drilling machines, or industrial other tool machines.

Remember: safety is everyone’s responsibility; follow the best practices to ensure a safe working environment.

For a free consultation with our drilling automation specialists, contact PROMOTECH INDIA at +91- 966 7660 304.