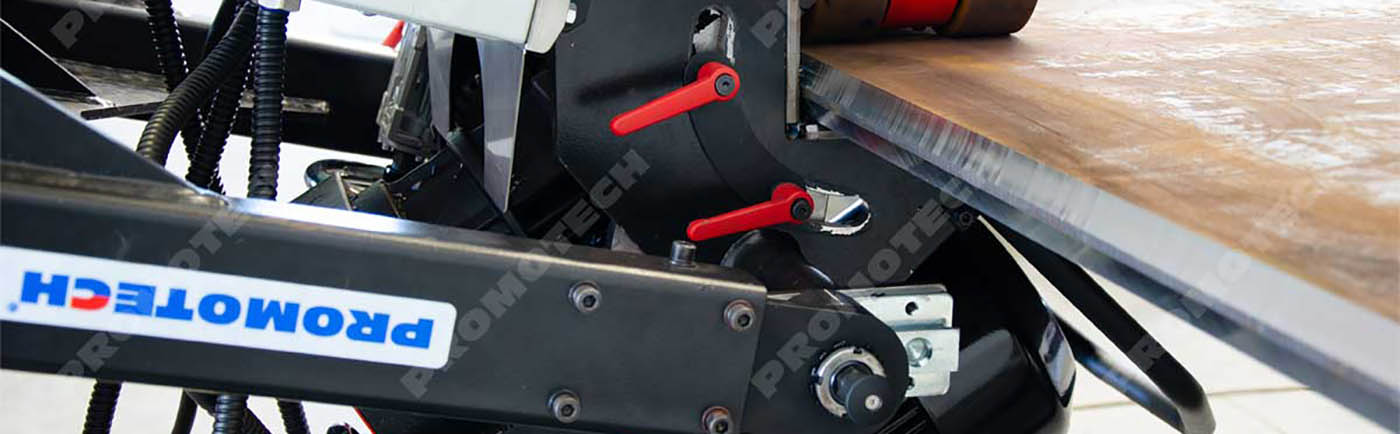

ABM 50 – Plate beveling machine – Suitable for Nickel alloys

Plate beveling Machine Case study

Nickel-based temperature and corrosion resisting alloys can be difficult to machine and they do harden rapidly; they also generate high heat levels when being cut, and thanks to their high shear strengths, offer a higher resistance to metal removal milling process. Thanks to the RPM control and rigid structure of ABM50 plate beveling machine now we are able to bevel these materials like c276 hastelloy, TI grade 1&2 easily.

Few of our clients are using ABM-50 (Automatic Plate Beveling Machine) for Nickel cladded plates in which 2mm thick layer of c276 has been cladded on carbon steel plate. Due to the fusion of two materials the fusion point experience even higher hardness (shear strength) compare to c276.

Promotech’ s specially developed cutting insert for nickel alloys and HD cut oil makes it even more economical and easy for client to bevel such high strength metals.

Key Features of ABM -50 Plate Beveling Machine

- Auto-feed portable beveller.

- Real-time measurement and on-screen display of exact bevel geometry and cutting parameters,

- Bevel width up to 50 mm (2”) at 45 degrees.

- 180° inversion allows for creation of a double-sided bevel – no need to rotate or flip heavy material reduces material handling costs and improves shop safety

- Variable spindle speed for work on a variety of steel grades and thicknesses.

- Versatile and transportable on its own trolley.

- Equipped with milling head including 8 replaceable inserts.

Other Products – ABM -14 Plate Beveling, BM-20 Plate Beveling, ABM -28 Auto Feed Plate Bevelling, Plate Beveling, BM-15 Plate Beveling, PRO10-PB Plate Beveling Machines