Guided by valuable feedback from our business partners and end-users around the globe, we are ever-evolving and will continue to move forward at PROMOTECH. In doing so, we have made some key improvements to the RAIL BULL welding tractor

Combining modern technology with mechanical engineering, this equipment is designed to ensure maximum productivity while improving the safety and quality of railway infrastructure.

At its core, the Track Welding Tractor is an invaluable asset for railway track maintenance and construction. Designed for flash-butt welding, it is capable of precision work for all types of rail welding applications.

This technology is now indispensable in contemporary rail systems, where the durability of the tracks and their resistance to wear and tear are paramount to the long-term effectiveness and safety of the railway network.

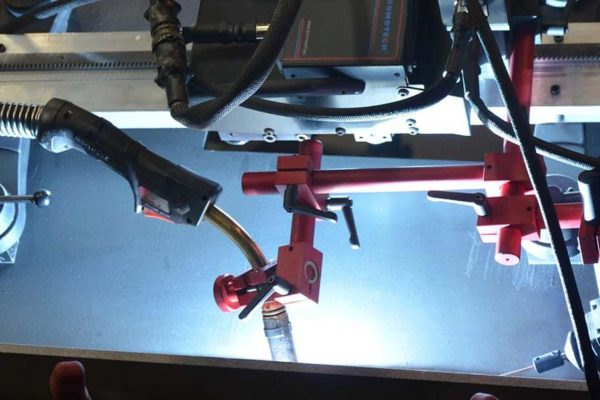

One of the most important parts of the Rail Bull Tractor is its oscillator, a sophisticated mechanism that is incorporated into the system to achieve smoother and more controlled welding. The oscillator plays a critical role in uniformly spreading welding heat along the surface of the rail, avoiding such problems as cracking, warping, or weld irregularities. This accuracy allows the welded joint to maintain the strength and integrity required to be able to bear the high stress and load imposed by passing trains.

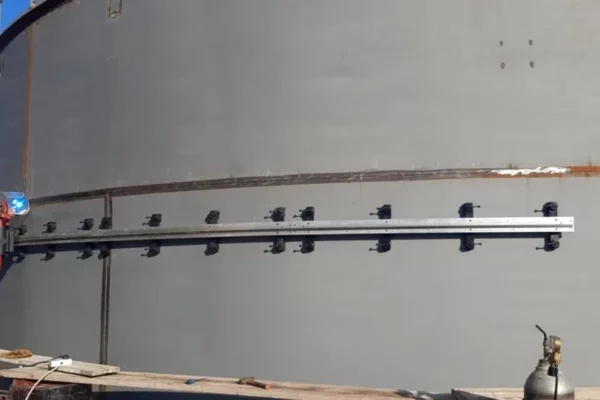

Magnetic fixtures hold the track in place on flat and curved ferromagnetic surfaces, and a vacuum track system provides secure clamping on non-ferromagnetic surfaces.

NEW DESIGN FEATURES

The RAIL BULL is designed heavy-duty and rugged to withstand the toughest working conditions. Its rugged build provides stability, strength, and durability against wear and tear. The most recent updates have improved its design, making the RAIL BULL more ergonomic and user-friendly while maintaining its reliable precision and performance.

WHAT’S NEW?

- New slimmer handles for better grip

- Re-engineered bottom/mounting plate

- New drive train design (no change in travel speed parameters)

- More robust power unit and on/off switch

- Non-split supply cable (mid-wire connector has been removed)

- Simplified cable anchor design

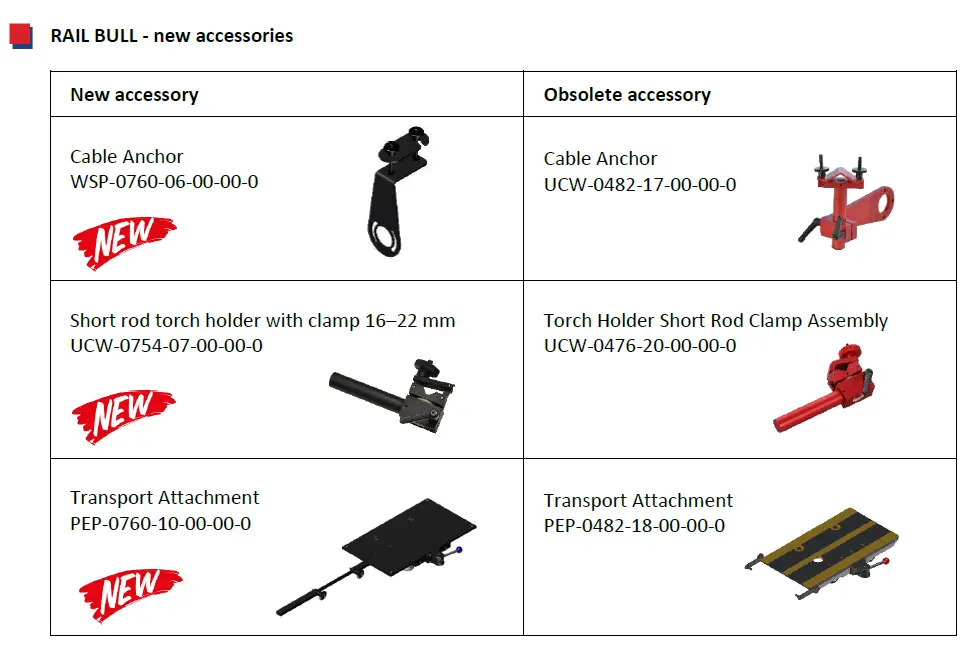

CHANGES IN ACCESSORIES

The new generation of RAIL BULL also brings improvements in accessory design, enhancing compatibility and performance.

ENHANCED ERGONOMICS, TRUSTED PERFORMANCE

The new RAIL BULL, featuring enhanced ergonomics, offers greater comfort and ease of use while maintaining its proven performance and technical specifications. It’s still the same powerful, efficient welding tractor, now with an upgraded design for improved usability.

The RAIL BULL retains all the key advantages of its predecessor, including:

- A closed-loop position control system with an electric motor and encoder for improved speed and positioning accuracy

- An integrated linear oscillator for weave welding and overlay

- A multifunctional LCD that displays process parameters and warnings

- A compact, lightweight design with a durable aluminum cast housing

- Convenient power supply options (115–230 V, 50–60 Hz or 42 V, 50–60 Hz)

- A 3-year warranty

The RAIL BULL welding tractor is capable of both straight and trapezoidal weld paths. It works on rigid or semi-flexible tracks and is suitable for a wide range of applications, including those with circumferential and irregular surfaces, handling radii as small as 5000 mm.

With a variety of accessories available, the RAIL BULL can accommodate torches with larger diameters and is compatible with both semi-flexible and rigid tracks, ensuring optimal performance across diverse applications.

The RAIL BULL Track Welding Tractor with Oscillator maintains the benchmark of precision, resilience, and performance in rail welding. With its new ergonomic refinements, user-friendlier design, and improved accessories, it remains an effective solution for contemporary railway construction.

From working on straight weld paths, trapezoidal weld paths, or irregular weld paths, the RAIL BULL offers improved performance with assured long-term outcomes. At PROMOTECH, our commitment to ongoing improvement guarantees that the RAIL BULL will be at the leading edge of rail welding technology for years to come.

If you are looking for tank welding solutions for your business, mail us at info@pfm.promotech.eu or visit https://promotech-india.in for more information.

ATEX drilling machines, ATEX and pneumatic drilling machines, Cordless Track Drilling Machine, Cordless Rail Drill Machine, battery core drill machine, compact drilling machine, Heavy Duty Tapping and Drilling Machine, portable drilling machine