A good weld starts with the right preparation of the pipe edges, and this is where bevelling comes in. The PRO-2 PB, PRO-5 PB, and PRO-10 PB bevelers are designed to deliver accuracy, reduce mistakes, and make the welding process more efficient, resulting in strong and reliable welds.

The Importance of Pipe Bevelling for Weld Quality and Strength

Pipe bevelling enhances the welding process. It expands the contact area, helps spread heat , and allows for deep penetration. This strengthens the weld and cuts down on flaws like bubbles or cracks. In contrast poor bevelling leads to weak connections, fusion problems trapped materials, and extra costs to fix mistakes.

Improved Precision and Efficiency

In the traditional method, producing a flawless bevel involved serious manual labor. But with PROMOTECH’s portable pipe bevelling machines PRO-2 PB, PRO-5 PB, and PRO-10 PB, the process now becomes more economical and convenient. These machines cover pipes of several materials such as carbon and stainless steel, aluminium alloys, copper-nickel, and have a single-point operation. Offering adjustable speed drives, they excel in performance dependent on material nature, wall thickness, and pipe diameter.

Designed for One-Person Operation

With their ergonomic and lightweight designs, these pipe bevellers are easy to use with either workshop conditions or site configurations. They offer precision and repeatability even in confined or tight areas, making them optimal for a wide range of applications. Solid and Robust Performance

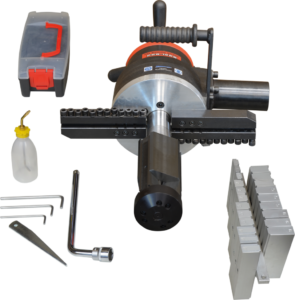

The newest line of PROMOTECH pipe bevellers comes equipped with a high-end spindle disc and double tool bit holders, both for improved tool stability as well as operational efficiency. In retaining all the capabilities of previous models, these machines promise smoother and less stress-sensitive operations, further improving workflow.

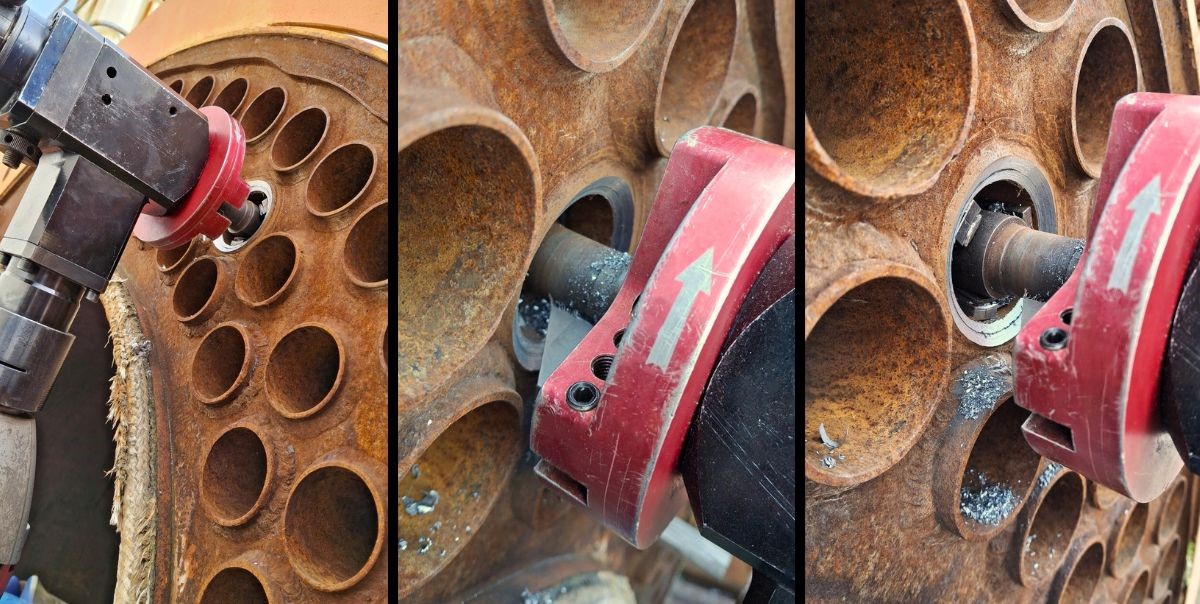

Self-Centering Expandable Mandrels for Consistency

Consistent positioning is needed for uniform bevels. PROMOTECH’s pipe bevellers meet this requirement using self-centering expandable ID-mounted mandrels. Stable positioning is maintained by this arrangement, cutting down setup time and enhancing productivity with a variety of operations.

J-Bevelling for Thick-Walled Pipes

Three Power Source Options for Flexibility

PROMOTECH’s PRO-2 PB, PRO-5 PB, and PRO-10 PB bevelers are equipped with three power source options:

Electric Motor – Low maintenance but needs a stable source of electrical power.

- Pneumatic Motor – High torque output, thus suitable for heavy-duty operations in areas with compressed air supply.

- CAS-Battery System – Ideal for areas without grid power, improving safety and mobility. The CAS system provides interchangeable batteries between different brands in the alliance, providing uninterrupted operation.

Versatile for Diverse Industries

These bevelling machines are extensively used in various industries such as energy production, shipbuilding, steel construction, and beverage manufacturing. Their versatility for working with different materials and jobs, along with a two-year warranty and post-warranty maintenance, makes them an investment that professionals will not regret.

New Generation of Portable Pipe Bevellers

The new PRO-2 PB model brings a new mandrel mounting system, eliminating the jaws, blocks, and springs of the old design in favor of expandable sleeves and spreaders. This new design makes setup easier, reduces transition times, and is more user-friendly. The PRO-2 PB also has an overload protection system with a wet multi-disk friction clutch, which protects the gear from harm.

Technical Specifications

- ID range: 19.5 – 38 mm (alternative: 15.5 – 22 mm, 38 – 58 mm)

- Max OD bevel width: 48 mm (alternative: 60.3 mm)

- Space-saving design well-suited for space-restricted environments, including boiler water walls

- ID range: 32 – 107 mm (alternative: 25 – 32 mm, 107 – 133 mm)

- Max OD bevel width: 114 mm (alternative: 140 mm)

- All-round product suitable for use in several bevelling forms including J-bevelling and internal calibration

- Range of IDs: 84 – 269 mm (alternative: 38 – 84 mm, 270 – 349 mm)

- Max OD bevel: 273 mm (alternative: 355 mm)

- Has provision for external and internal bevelling, J-bevelling, and flange-facing

Conclusion

With PRO-2 PB, PRO-5 PB, and PRO-10 PB pipe bevellers, PROMOTECH is raising the standards of efficiency and accuracy in pipe edge preparation. It ensures strong and high-quality welds, with minimal effort, with such machines that provide top performance for automated welding processes such as orbital or complex industrial applications. The modern design along with the user-friendly aspect is the major factor for those industries where exact and dependable pipe setting up is essential.

Want to see how the right beveling equipment could transform safety in your operation? PROMOTECH has the answers you’re looking for.