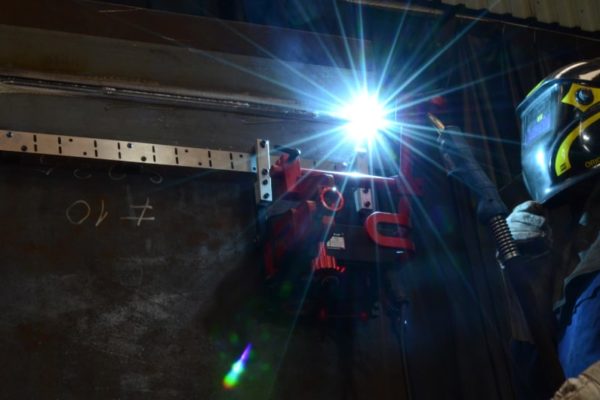

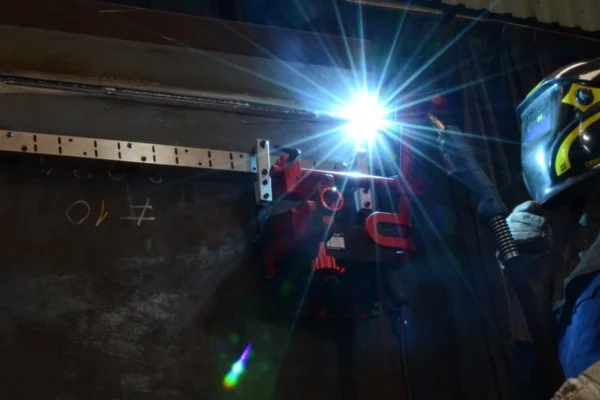

The demand for accuracy and efficiency in welding procedures is increasing as industrial automation evolves. PROMOTECH INDIA’s GECKO Compact Welding Carriage is a trackless welding tractor designed for portable use, enhancing efficiency without compromising welding quality. Since the GECKO WELDING CARRIAGE is meant for industry, the need for companies seeking to improve welding procedures is a must.

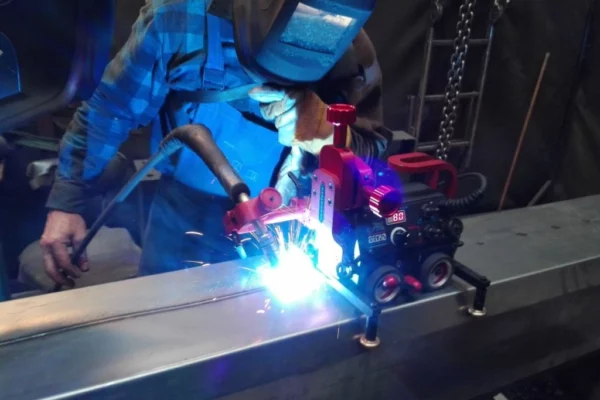

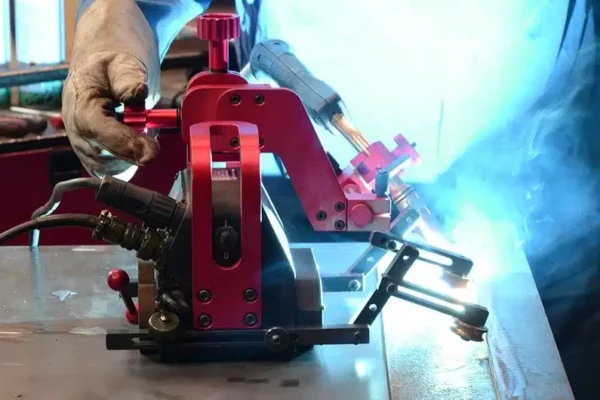

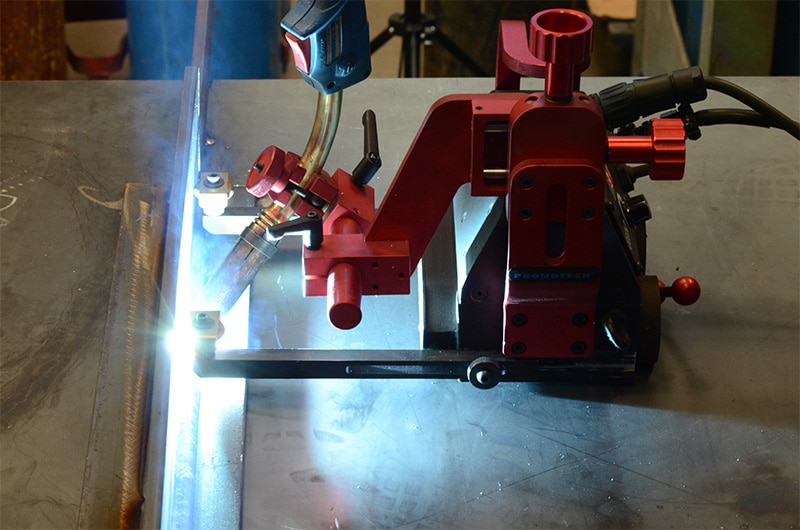

The GECKO Welding Carriage features a 4-wheel drive magnetic traction system that utilizes magnetic forces to provide both stability and agility. This is especially helpful for out-of-position welding since it allows operators to weld at different angles without compromising performance. The Gecko’s design places a high value on portability, at only 8 kg.

Gecko’s closed-loop speed control is one of its most impressive aspects. This process maintains a uniform application of heat for welding by controlling the carriage’s travel speed. Producing high-quality welds that meet specific specifications requires consistency. This reduces the amount of filler metal required, which decreases the risk of costly over-welding. This feature can yield significant cost savings in businesses where materials are costly.

GECKO Welding Carriage has a multipurpose LED display to enhance use. Welders may easily access diagnostic information and switch between units. They can also monitor travel speed thanks to this user-friendly interface. This increases productivity and improves user experience by keeping operators informed while welding.

The torch pre-setting to activate the arc is another new feature. The user can preset the time to start the welding arc, which is the electrical discharge that melts the metal, before and after the carriage moves, by up to five seconds. This feature ensures the beginning and end of each weld have enough material, resulting in a clean, polished finish that meets standards. This added control improves the final weld quality.

Versatility is one of the key aspects of Gecko’s design. The welding carriage can be used in various contexts and applications due to the wide range of accessories that are offered. The GECKO Welding Carriage can be adjusted to meet specific needs, like construction or repair of structural components, so it can tackle the varying demands of each industrial operation.

GECKO Welding Carriage is simple to operate in any range of work conditions due to its adaptable power supply modes (115–230 V or 42 V, both 50–60 Hz

TYPES OF GECKO VERSION:

Gecko | Compact Welding Carriage –

A portable trackless welding tractor with a 4-wheel drive system with magnetic traction and a control loop feedback mechanism that stabilizes speed in all welding positions is the Gecko | Compact Welding Carriage. A weld bead shape that is precisely according to the requirements is made possible by constant, continuous, and repeatable travel speed, which significantly lowers the cost of overwelding and the need for filler metal.

To produce a desired weld fill at both ends, users can choose an arc ignition period (up to 5 seconds) at the beginning and the end of the tractor travel path. Gecko is adaptable to many roles and uses because of its extensive accessory selection

Gecko Battery 2 | Cordless Welding Tractor –

Using MIG/MAG torches, the GECKO BATTERY 2 is a battery-operated trackless welding tractor that can continuously weld butt and fillet. Without the need for wires, the CAS LiHD battery provides sufficient power to manage even the most demanding tasks. In different welding positions, speed stability is provided by a 4-wheel drive system with magnetic traction and a feedback loop. A weld bead shape that is precisely according to the requirements is made possible by constant, continuous, and repeatable travel speed, which lowers the expense of overwelding and significantly reduces the use of filler metal. To produce a desired weld fill at both ends, users can choose arc ignition periods of up to five seconds at the beginning and conclusion of tractor movement. An external OSC-8 PRO pendulum oscillator that may be powered by the integrated oscillator socket is ready to be installed in GECKO Battery 2.

Wide Range of Welding Positions

- PA / 1F / 1G – Flat Position (welding on a flat surface)

- PB / 2F – Horizontal Fillet Position (welding on a horizontal surface where two pieces meet at an angle)

- PC / 2G – Horizontal Groove Position (groove welds done horizontally)

- PD / 4F – Overhead Fillet Position (welding overhead where two pieces meet)

- PE / 4G – Overhead Groove Position (overhead groove welds)

- PF / 3G – Vertical Up Groove Position (groove welds done vertically upward)

RANGE OF WELDING APPLICATIONS

The GECKO welding carriage is adaptable to handle a wide range of applications, including out-of-position welding, and can be used for a variety of tasks.

Its strong magnetic traction and 4-wheel drive mechanism guarantee constant contact with the workpiece. Furthermore, even when welding vertically, overhead, or out of position, the computerized speed control system with an integrated feedback loop keeps the trip speed constant.

For easy and clear monitoring, a multipurpose LED display shows system notifications in addition to real and specified travel speeds.

To produce a desired weld fill at both ends, users can choose arc ignition periods of up to five seconds at the beginning and finish of the GECKO trip.

During lengthy or multi-pass welding, the carriage’s heat-resistant rubber wheels provide steady and smooth mobility, especially in situations when the tractor approaches the hot weld seam. Because silicone wheels are thermally resistant, they keep their grip and form in hot conditions, which minimizes wear, the need for frequent replacements, and downtime.

Stainless steel wheels are an optional feature when welding horizontally on a plate that has been heated (KOL-0466-72-00-00-0).

TRACKS

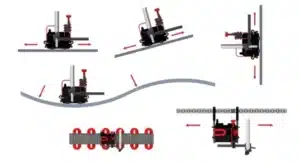

Self-guiding roller arms do away with the need for track, and a permanent magnet at the bottom of the carriage guarantees correct adhesion to ferromagnetic surfaces. Complex assemblies like circumferential and uneven surface applications down to minimum radii of 600 mm (when working outdoors) and 800 mm (when working indoors) are ideally suited for GECKO.

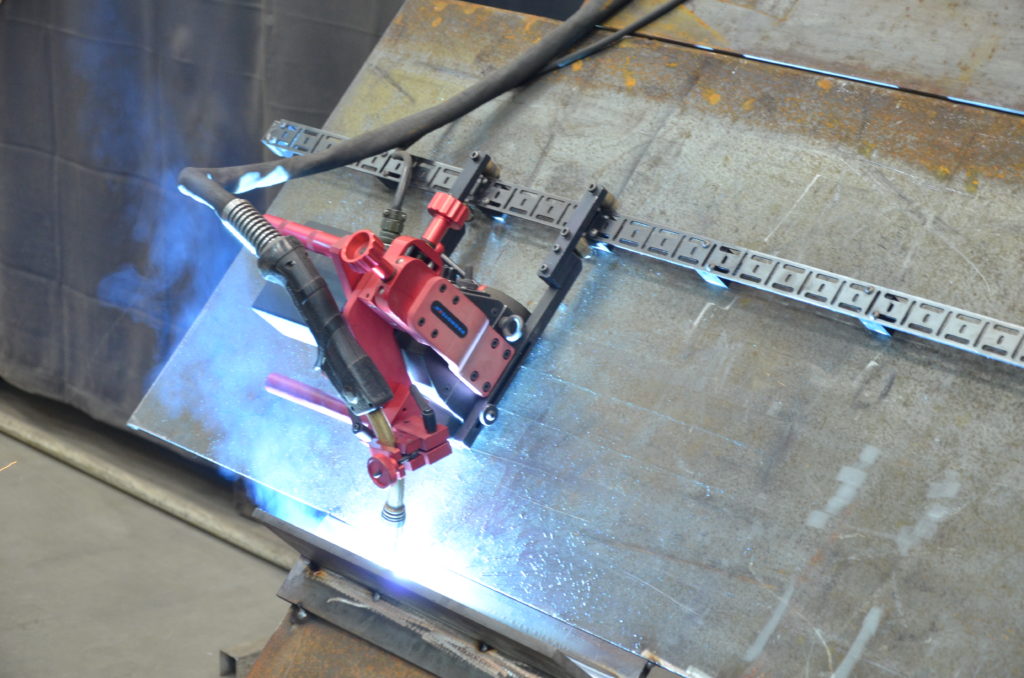

FLEXIBLE TRACKS

Magnetic blocks can be used to mount a flexible track to aferromagnetic work surface. It enables the carriage to be guided straight ahead on level surfaces as well as on tanks and pipes. One flexible guide measures 1.85 meters (6 feet) in length. One meter (3.3 feet) is its minimum curve radius.

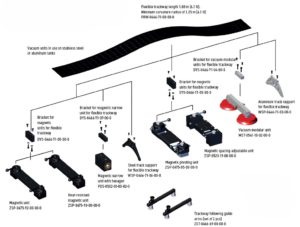

FLEXIBLE TRACKWAY

The carriage can move on both ferrous and non-ferrous materials using magnetic or vacuum units by using an optional flexible trackway set. A single flexible rail has a minimum curve radius of 1.25 meters (4.1 feet) and a length of 1.88 meters (6.1 feet). It can be clamped to tanks, pipelines, or flat surfaces.

SYSTEM OF VACCUM TRACKS

The vacuum track system can be used to clamp flexible trackways, such as aluminum and stainless steel, where magnetic clamping is not an option. The vacuum units guarantee safe attachment to non-ferromagnetic surfaces when used in conjunction with a vacuum pump.

The vacuum track system can be used to clamp flexible trackways, such as aluminum and stainless steel, where magnetic clamping is not an option. The vacuum units guarantee safe attachment to non-ferromagnetic surfaces when used in conjunction with a vacuum pump.

The device offers a holding force of up to 1400 N at ordinary atmospheric pressure at sea level and a gauge pressure of -0.7 bar. Please be aware that as altitude increases, this holding force reduces. Additional vacuum units can be used to strengthen the trackway’s overall gripping strength.

CONCLUSION

At the end of the day, welding is all about precision, consistency, and saving time without cutting corners. That’s exactly what PROMOTECH INDIA’s GECKO Welding Carriage brings to the table. Lightweight, versatile, and built for real-world challenges, it helps welders focus on the job instead of worrying about errors or inefficiency. Whether you’re working in construction, repair, or heavy industry, the GECKO makes every weld cleaner, faster, and more reliable.

✨ Ready to take your welding to the next level? Explore the full range here: https://promotech-india.in contact us at +91 96676 60304