A sturdy, self-driven bevelling machine, the ABM-50 DD Vario is made for sectors that require precision, durability, and reliability. It can produce smooth, superior bevels up to 50 mm wide and is designed to withstand heavy-duty applications without generating heat or altering the material’s fundamental characteristics.

This equipment produces reliable results with minimal manual labour, whether used for precise weld preparation in a fabrication facility or for large structural steel plates.

Designed for Sturdy Materials and Heavy Plates

The ABM-50 DD Vario is perfect for tough industrial settings because it can handle plate thicknesses between 8 and 80 mm. It works well on a variety of materials, such as:

- Carbon steel

- Stainless Steel

- Duplex steel

- High-strength steels, such as Hardox

Because of its adaptability, it is a dependable option for infrastructure, heavy fabrication, shipbuilding, and construction projects.

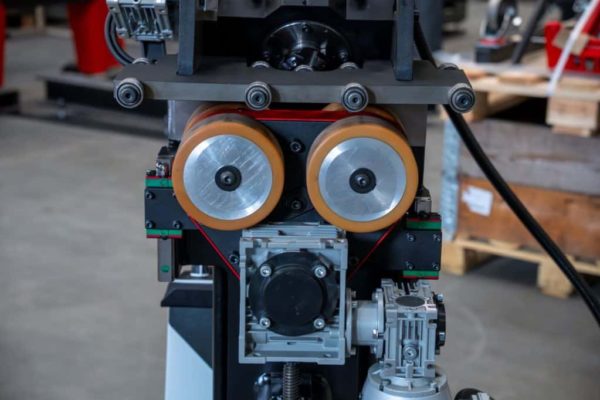

Automated Travel for Reliable Outcomes

The machine can go up to 1.2 meters per minute smoothly along the plate edge thanks to its auto-feed drive mechanism. In addition to guaranteeing consistent bevel quality across lengthy workpieces, this greatly lessens operator fatigue.

Additionally, spring-loaded castors ensure the machine’s stability and cutting accuracy throughout the operation by automatically adjusting to small alignment problems or uneven floors.

Clean Bevels Using Cold Milling Technology

The ABM-50 DD Vario employs rotary milling technology rather than thermal cutting techniques such as gas or plasma. Clean, accurate bevels free of heat-affected zones (HAZ) are produced by this mechanical method.

Consequently:

- The strength of the material is unaffected.

- Consistent and weld-ready surface finish

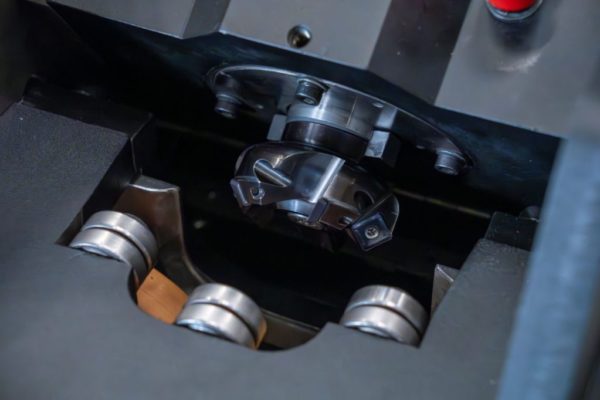

Extended Tool Life with Indexable Inserts

The milling head is equipped with five 4-sided indexable cutting inserts, allowing quick rotation or replacement of each insert with ease. This smart design reduces downtime, maximizes tool utilization, and helps keep operational costs under control.

To deliver smooth cutting performance and excellent surface finish across different steel grades, multiple insert options are available to suit specific material requirements:

-

- PLY-000781 – Cermet cutting insert for steel

- PLY-000835 – Cutting insert for stainless steel

- PLY-000591 – Heavy-duty cutting insert

Flexible Bevel Angle Adjustment

ABM-50 DD Vario provides:

- Spindle speed can be adjusted between 500 and 1450 RPM.

- Adaptable feed rate for maximum cutting efficiency

- Because of this flexibility, operators can adjust the machine according to the requirements of the job and the grade of the material.

Extended Tool Life with Indexable Inserts

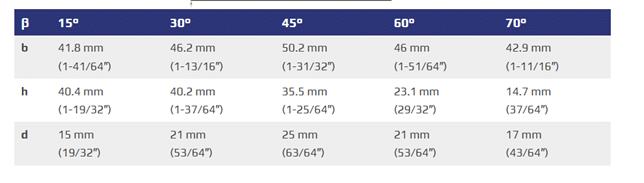

The continuous bevel angle adjustment range for the ABM-50 DD and ABM-50 DD Vario is 15° to 70°. This enables customers to attain various bevel profiles based on project requirements and weld design.

The final shape of the bevel is determined by:

- The bevel angle

- Depth of bevel

- The width of the bevel

Built-in LED Load Monitoring

The equipment has an LED overload indicator to safeguard the milling mechanism and motor:

- Green: Ideal load

- Yellow: Getting close to the limit

- Red: Overload alert

Operators are able to prolong machine life and ensure safe working conditions thanks to this real-time feedback.

The ABM-50 DD Vario: Why Choose It?

Power, accuracy, and user-friendliness are all combined in the ABM-50 DD Vario. It lowers operating expenses and increases productivity by eliminating heat-related issues and reducing manual labour.

It’s a substitute of thermal or manual edge preparation methods, it not only streamlines the workflow but also delivers meaningful savings in time, effort, and overall operating costs—making it a smart, future-ready choice for modern fabrication environments.

Important Technical Features

- Auto-feed mechanism that moves on its own (up to 1.2 m/min)

- The bevel angle is continuously changeable between 15° and 70°.

- 50 mm at 45° is the maximum bevel width.

- Capacity for plate thickness: 8–80 mm

- 840–1040 mm is the adjustable working height.

- Indexable cutting inserts for cold milling

- A system for monitoring LED overload

- The ability to operate stationarily on smaller workpieces

Watch Full Video – https://youtu.be/XMXPiVmjptU